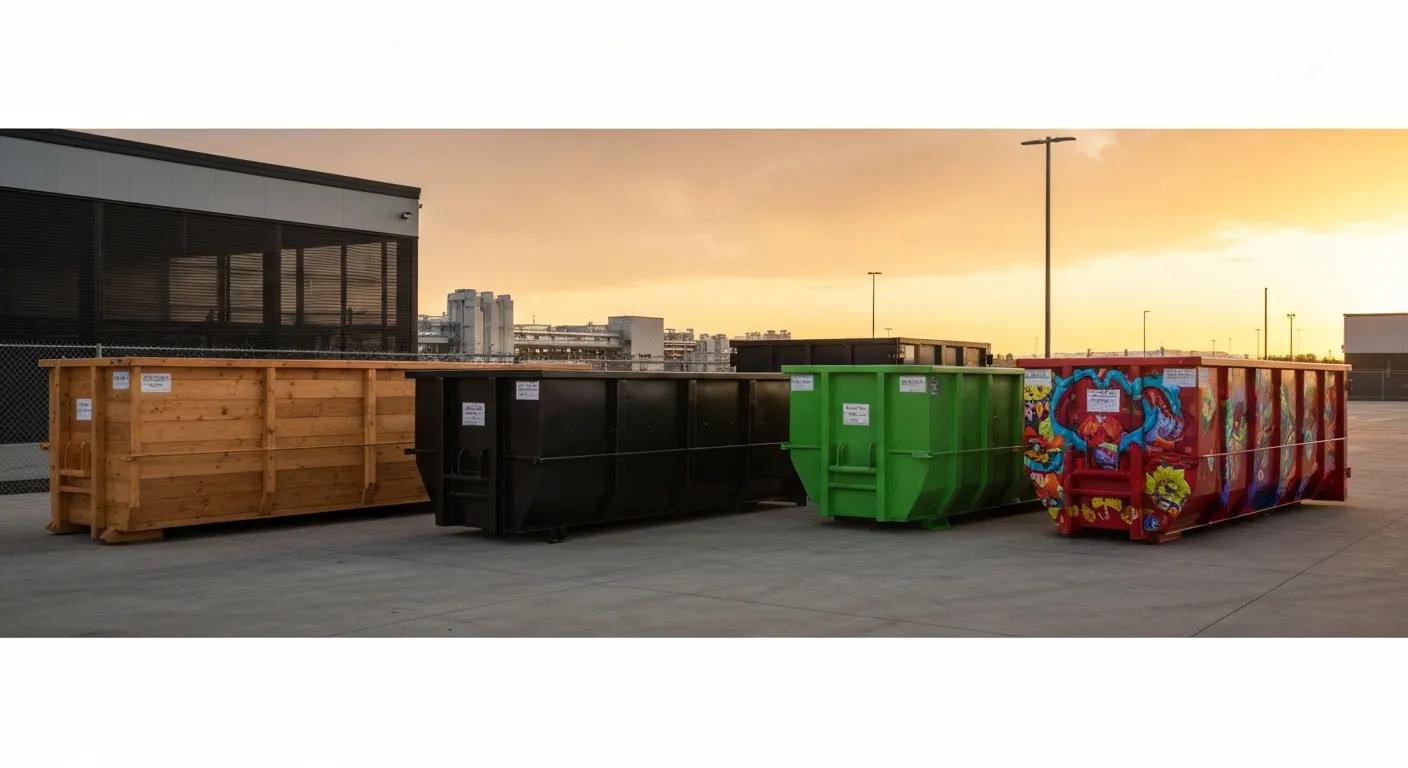

Specialty Dumpsters for Construction Projects

Specialty Dumpsters for Construction Projects

Specialty dumpsters are purpose-built containers made to handle specific construction materials, heavy debris, or tight site conditions that standard dumpsters can’t manage safely or efficiently. The right container improves on-site safety, cuts hauling costs, and keeps your project compliant with local disposal rules by matching design to material weight, access limits, and recycling goals. This guide walks you through the common specialty dumpster types, how size and weight influence efficiency, and which materials need special handling on Long Island jobs. You’ll find clear decision steps, disposal pathways by material, and a side-by-side look at roll-off, heavy-debris, low-boy, compactor, and front-load options. We also cover Long Island specifics—permits, transfer-station rules, and scheduling—and show how a local provider can help with permitting, delivery/pickup, and diversion paperwork. Keywords like specialty dumpsters for construction waste, construction dumpster sizes, and dumpster rental Long Island construction are included to help you pick the right container for each build or demo phase.

What Types of Specialty Dumpsters Are Used for Construction Projects?

Specialty dumpsters come in several types built for access, weight, or compaction needs: roll-offs for mixed demolition debris; heavy-debris or inert containers for concrete and soil; low-boy units for driveway-friendly placement; compactors for ongoing volume reduction; and front-load bins for routine commercial pickups. Each type solves a specific site constraint—low clearance, high material density, or fewer hauls—and those choices affect labor, transport cost, and recycling results. Knowing the differences lowers permit risk and helps teams match container capacity to material weight and site geometry. Below is a short list of the main types with a quick benefit for each to help you decide before we dig into details.

- Roll-off dumpsters — open-top, easy loading for demolition and renovation debris.

- Heavy-debris / inert dumpsters — reinforced for dense materials like concrete and soil.

- Low-boy dumpsters — low profile to protect driveways and fit under low clearances.

- Compactor dumpsters — mechanically compress loose waste to cut haul frequency.

- Front-load dumpsters — scheduled pickups for commercial sites and offices.

Together these options form a practical toolkit for matching site constraints to container capabilities. The next sections explain each subtype and when to use it.

What Are Roll-Off Dumpsters and Why Are They Popular for Building Projects?

Roll-off dumpsters are open-top containers delivered on a wheeled chassis that slide off the truck for quick placement and removal. They come in sizes typically from 10 to 40 cubic yards, making them a go-to for demolition, renovation, and mixed-waste jobs where easy loading and visual inspection matter. Crews can toss bulky items directly into a roll-off, speeding cleanup during busy phases. Keep in mind weight limits for dense materials such as concrete or soil—those can trigger surcharges. On Long Island, roll-offs offer flexible sizing but you should confirm weight allowances and recycling options up front to avoid unexpected fees.

How Do Heavy Debris Dumpsters Handle Concrete, Dirt, and Asphalt Waste?

Heavy-debris (inert) dumpsters have reinforced floors and walls and are rated for dense materials by weight rather than just volume. That structural strength prevents deformation in transport and lowers safety risk. Concrete, dirt, and asphalt weigh far more per cubic yard than wood or drywall, so these containers and their hauling contracts factor in tonnage limits and possible weight surcharges. Many recycling pathways exist—concrete and asphalt can often be crushed and reused—so keeping those materials separate in the right container can reduce landfill costs and support diversion goals. Proper planning means estimating mass, choosing a rated dumpster, and verifying transfer-station acceptance before loading.

What Are Low-Boy Dumpsters and When Are They Ideal for Construction Sites?

Low-boy dumpsters are low-profile units designed to protect driveways, fit under low clearances, and lower load height for safer tossing and loading. Their reduced height and gentler base or wheel setup make them a good fit for residential renovations, sensitive surfaces, and properties with tight maneuvering room—reducing the chance of surface damage during placement and pickup. There’s a capacity trade-off: low-boy units often hold less volume than a standard roll-off with the same footprint, so balance surface protection against haul frequency. In Long Island’s dense neighborhoods, low-boys help preserve access and meet placement rules—but always confirm curb or street permit needs early in the plan.

How Do Compactor and Front-Load Dumpsters Support Large-Scale Construction Waste?

Compactor dumpsters use mechanical compression to shrink lightweight, bulky debris—cardboard, packaging, and loose wood—so you haul less often and lower transport costs on long-duration jobs. They need power and clearance for the compaction gear, so they suit sites with stable infrastructure and steady waste generation, like multifamily builds or large renovations. Front-load dumpsters are standard containers collected on a routine schedule and are useful for site offices or trade-specific streams. Both options improve efficiency for continuous waste streams, but compactors require upfront planning for power and placement in your site layout.

How Do Construction Dumpster Sizes Affect Project Efficiency and Waste Management?

Container size affects crew flow, on-site staging, haul frequency, and total project cost. Picking the right size reduces double handling and avoids schedule delays from overfills or surprise pickups. Common sizes—10, 20, 30, and 40 cubic yards—map to different project types and crew habits, but material density remains the deciding factor: a small dumpster can hit weight limits fast if loaded with concrete versus lightweight roofing. Start by estimating debris volume, adjust for density, then check space and permit limits before you choose a size.

This quick reference helps match expected debris to capacity. When in doubt, choosing one size larger often avoids costly extra hauls; the next section breaks decision factors down further.

What Are the Common Construction Dumpster Sizes and Their Ideal Uses?

Construction dumpster sizes typically run from 10 to 40 cubic yards and align with project scale: 10-yard units suit small renovation debris, 20-yard containers handle moderate remodels or roof tear-offs, 30-yard dumpsters work for larger renovations or light demolition, and 40-yard roll-offs fit full demolitions and major new construction. Size choice should also factor site access, driveway protection, and local curb-permit rules—parking a 40-yard on a narrow residential street may require permission that a smaller container avoids. Estimate conservatively and ask your provider about weight ratings; when unsure, go one size up to limit mid-project swaps.

What Factors Should You Consider When Choosing Dumpster Size?

Pick dumpster size based on material type and density, project timeline and phasing, available on-site space and access, and local permitting for street or driveway placement. Density matters because heavy inert waste reaches weight limits faster than bulky light materials; phasing can spread debris across multiple pickups to avoid overweight fees. Tight entries, low clearances, and fragile driveways push you toward low-profile or smaller containers, while long projects with steady waste may benefit from scheduled front-loads or compactors. Budget for rental rates plus estimated haul fees tied to tonnage and the operational cost of swapping containers mid-job.

What Types of Construction Waste Require Specialty Dumpsters?

Certain waste streams need specific containers or disposal paths: inert materials like concrete and soil require heavy-debris rated dumpsters; recyclable streams such as metal and asphalt do best in segregated containers for recovery; mixed demolition commonly goes in roll-offs; hazardous wastes must be handled by specialists and never mixed with general construction debris. Correct classification affects permitting, transfer-station acceptance, and possible recycling revenue—so sort on-site and coordinate with your disposal partner early to stay compliant and control costs.

Separating materials by type helps projects maximize recycling, cut landfill tonnage, and meet local disposal rules.

What Are the Most Common Construction Debris Types?

Typical construction waste includes wood framing and scrap, concrete and masonry, metals, drywall, roofing materials, and asphalt from paving work. Each material has a common density and recycling route: metals often fetch recycling value, concrete and asphalt can become aggregate, and clean wood may be reused or chipped. Knowing which debris will dominate your job lets you plan container counts and types—for example, a demo heavy on concrete needs heavy-debris dumpsters rather than standard roll-offs. Good pre-planning reduces cross-contamination and disposal costs.

How Do Hazardous and Non-Hazardous Construction Wastes Differ?

Hazardous construction waste—examples include asbestos, lead-based paint chips, certain contaminated soils, and chemical solvents—requires special handling, manifesting, and disposal at licensed facilities under strict rules. Non-hazardous wastes like clean wood, metal, dry drywall, and most concrete follow standard municipal or commercial recycling and landfill paths with fewer controls. If you suspect hazardous materials, stop work, test, and call certified abatement specialists; improper disposal can bring fines and delays. For most jobs, separate suspect materials at the point of generation and notify your disposal partner for safe, compliant handling.

How Can Specialty Dumpsters Improve Construction Waste Management on Long Island?

On Long Island, choosing the right specialty dumpster helps you comply with Suffolk and Nassau county transfer-station rules, manage street-placement and curb-permit needs, and pursue diversion strategies where facilities accept crushed concrete or asphalt. Local providers who work in-region can guide you on county permit forms, transfer-station acceptance, and scheduling windows that align with hauling restrictions. The correct container reduces haul frequency, limits permit headaches, and supports diversion reporting for commercial projects. Below are practical local items to consider early in your planning.

- Verify county and municipal permit requirements for curbside placement in Suffolk and Nassau counties.

- Confirm transfer-station acceptance for dense materials and available recycling facilities.

- Schedule deliveries and pickups to fit local hauling rules and minimize street congestion.

What Local Regulations Affect Dumpster Placement and Waste Disposal in Long Island?

Long Island projects must follow municipal and county rules for on-street placement, curb permits, and time-of-day restrictions that affect dumpster siting and duration. Transfer stations and recycling facilities in Suffolk and Nassau counties set specific acceptance policies for heavy debris like concrete and asphalt, and some require pre-authorization for large or contaminated loads. Plan permit lead time into your schedule to avoid demo stoppages, and coordinate with your hauler to secure compliant placement and disposal routes—this reduces the chance of rejected loads or surprise fees.

How Does Long Island Dumpster Rental Bros Support Efficient Specialty Dumpster Services?

Dumpster Rental Long Island Bros brings local knowledge to construction waste management with a range of construction dumpsters, reliable pickup and delivery scheduling, and transparent pricing to help contractors control costs while following regional rules. We offer multiple dumpster sizes—including 40-yard roll-offs for large demolition—and junk removal services to clear mixed materials quickly. Our team helps customers pick the right rated dumpster for heavy debris, times permits in Suffolk and Nassau, and coordinates recycling when transfer stations accept crushed concrete or metal streams. That local experience shortens response times, reduces risk, and simplifies diversion documentation.

What Are Best Practices for Choosing and Using Specialty Dumpsters on Construction Sites?

- Estimate and segregate: Project volumes by material and assign dedicated containers for concrete, metal, wood, and mixed debris.

- Protect placement surfaces: Use low-boy units or protective boards to prevent driveway damage and secure curb permits for street placement.

- Schedule pickups to phases: Time drop-off and haul-away with demolition and finishing phases to avoid overfill or idle containers.

- Verify weight ratings and facility acceptance: Ask your provider about tonnage limits and transfer-station rules for dense materials.

Following this checklist lowers disposal costs, speeds site turnover, and raises recycling rates. The sections that follow cover segregation and loading tactics in more detail.

How Should Construction Waste Be Segregated for Effective Dumpster Use?

Segregate materials into concrete/inert, wood, metal, recyclable roofing, and hazardous streams to boost recycling and avoid contamination that causes rejected loads or extra fees. On-site tactics include clearly labeled containers with simple signage, small separation bins for trim carpentry, and a staging area for metal salvage. Train crews to sort at point-of-generation and use quick visual guides at each container—this reduces cross-contamination and supports diversion documentation, often saving money when recyclables like metal stay clean and separate.

What Are Tips for Maximizing Dumpster Space and Managing Heavy Materials?

Maximize space by breaking down large items—cut framing to fit, lay drywall flat, and stack shingles to reduce air gaps—while distributing heavy materials evenly to avoid axle overloads and respect weight ratings. For bulky but light materials, use a larger volume container; for dense debris, select a heavy-debris dumpster or plan multiple smaller loads to stay under weight limits. Safety first: don’t overload sidewalls, keep loads below the container rim, and spread weight evenly to prevent tipping in transport. When unsure, check with your rental partner to confirm sizing and rates for your material mix.

Frequently Asked Questions

Specialty dumpsters improve site safety, help you meet local rules, and save money over time. Using containers designed for specific materials—heavy debris, recyclables, or low-clearance sites—reduces accidents, ensures correct disposal, and streamlines the waste flow so you haul less often. The right dumpster keeps the site organized and helps projects finish on schedule.

Start by checking local permit requirements for curbside placement and the transfer station acceptance rules in your county. Work with a local rental provider—many have experience with regional paperwork and can guide you through permits and approvals. Allow time for permit processing and confirm any material restrictions up front to avoid fines or delays.

If you find suspected hazardous materials, stop work and assess the situation. Call a certified hazardous-waste specialist to identify and handle the material—do not place hazardous items in regular dumpsters. Proper testing, documentation, and licensed disposal are essential to protect workers and stay compliant.

Estimate volume by measuring the areas being renovated or demolished and calculating likely debris. Factor in material density—concrete takes up less space but weighs more than wood—and add a buffer for unexpected waste. Your dumpster provider can offer guidance based on similar projects and help pick the right container size.

Break down large items to save space, put heavy materials at the bottom, and load systematically from back to front. Keep the load below the top edge and spread weight evenly to avoid tipping and weight penalties. Proper loading saves space and prevents extra fees.

Yes. Many rental companies offer containers sized for home renovations, cleanouts, and landscaping. Consider project size and material types, and check local placement and permit rules if the dumpster goes on a public street or sidewalk. A local provider can recommend the right unit for your job.

Recycling construction waste reduces landfill impact and can lower disposal costs. Materials like concrete, metal, and clean wood are often recyclable. To maximize recycling, separate materials on-site and use dedicated containers. Check local facility acceptance and pre-approve large loads when required; your rental partner can help identify options.

A specialty dumpster is a container engineered for particular materials or site constraints—examples include heavy-debris/inert dumpsters for dense loads, low-boy containers for driveway-friendly placement, compactors for volume reduction, and roll-offs sized for demolition. The “specialty” label comes from design features such as reinforced floors, lower height, compaction mechanisms, or specific loading access that address weight, footprint, or operational needs on construction sites. Choosing a specialty dumpster aligns container capability with project requirements to reduce cost and compliance risk.

You can put dirt and concrete in roll-off dumpsters only when the container and rental agreement explicitly allow heavy materials and your provider confirms the weight rating and transfer-station acceptance. Dirt and concrete are dense and often trigger weight-based surcharges or require separate handling. For large volumes of inert material, a heavy-debris dumpster or direct delivery to a crushing/recycling facility is usually more cost-effective and avoids rejected loads.

Use a three-step approach: estimate debris volume from the project scope, adjust for material density (heavy vs. bulky), and assess site access and permit constraints. Then choose a container that minimizes swaps while complying with local placement rules. Examples: small kitchen remodels often fit a 10- or 20-yard unit; roof tear-offs typically need 20 yards for bulky shingles; full demolitions often require 40-yard roll-offs or heavy-debris rated containers. After estimating, request a local quote to confirm weight allowances, permit needs, and pickup windows.

For Long Island jobs, request quotes that list dumpster type, weight limits, pickup windows, and any county-specific permit support so you get predictable disposal costs and smooth implementation.

Conclusion

Using specialty dumpsters on construction projects improves safety, keeps you compliant, and often cuts disposal costs by matching container capability to material needs. That tailored approach simplifies job-site waste handling and supports recycling goals, keeping work moving. Partnering with a local provider who knows Long Island rules and transfer-station practices makes implementation easier—reach out to explore specialty dumpster options that fit your next build or demolition.